Conical Ball End Mill

Applicable processing materials

Suitable for processing plastic, foam, polyurethane, polyethylene, etc.

Multi-blade edge design

All are delicately processed, 4 water chestnut and 6 water chestnut, long-lasting

Knife edge mirror design

Precision precision grinding, professional cutting edge design to improve processing efficiency

Strong wear resistance

High temperature quenching grinding production quality and service life increase

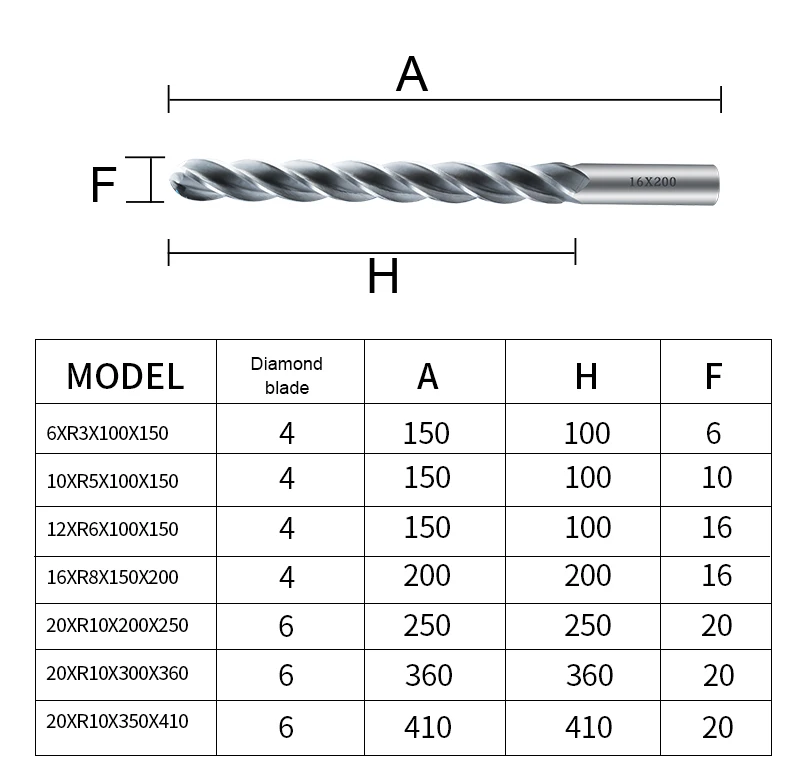

Tool selection

To achieve the purpose you require, be sure to use short-edged tools as much as possible. Too long cutting edge or too long tool body will cause vibration and deviation during machining, which will lead to tool damage and affect the quality of machining. We recommend using a tool with a larger shank diameter

Tool operation

1. The woodworking milling cutter is designed for portable and desktop engraving machines and cannot be used on machines such as electric drills.

2. The tool can process hardwood, softwood, synthetic board and other wood to produce a smooth surface, but avoid processing metal materials such as copper, iron, and non-wood materials such as sand and stone.

3. It is necessary to use a suitable size jacket, because the jacket with serious wear, insufficient roundness and taper in the inner hole can not provide enough clamping force, which will cause vibration or break the tool handle and fly off.

4. Do not think that the new jacket must be safe and reliable. When the tool handle is found to have uneven contact marks or grooves after the tool is clamped, it indicates that there is slippage and deformation of the inner hole of the jacket. This is to replace the jacket immediately to avoid accidents.

5. After the tool is clamped, if the tool is found to be bounced when it is working, stop it immediately, repeat the clamping several times so that the tool shank and the jacket get sufficient contact, and then work.

6.The contact between the tool shank and the jacket should be good. The tool shank must be completely inserted into the jacket and tightened firmly, so as to provide sufficient clamping force for the tool, and not only a small part of it can be inserted into the jacket, otherwise it will be easy The tool handle is broken and the tool is damaged.

7. Use proper eye and ear protection devices during operation.

8.Body, clothes and other sundries should not be close to the working tool.

Company information and contact information

Jinan Hongyang CNC Machinery Co., Ltd. was established in 2015. There are more than 100 employees, and the inventory area is 10,000 square meters. It is mainly engaged in engraving machine parts, including spindle motor, frequency converter, stepper motor, drive, hybrid servo motor, servo motor, Richauto dsp series controller, weihong or nc studio controller, spindle cooling water pump, lubricating oil pump, tool sensor, Limit sensors, water-cooled vacuum pumps, air-cooled vacuum pumps, power supplies, transformers, gear boxes, racks, rails, sliders or blocks, ISO30 tool clips, cable chains, spindle dust covers, vacuum cleaners and other engraving machine accessories, welcome you for inquiries.

Conical Ball End Mill

Sale price$100.41

Regular price$0.00 (/)